GRAYHILL TEST LABS

For physical and environmental stresses, our equipment and expertise permit fast and accurate verification to MIL-STD 202 and 810, IEC 68 and 60529, RTCA-DO160, ISO 16750, NEMA, UL, and ANSI/ASEA EP455 standards for the following tests:

– Operating temperature

– Thermal cycling

– Storage temperature

– Thermal shock

– Altitude (barometric pressure)

– UV resistance

– Seal/ingress protection: moisture, dirt, and dust

– Humidity

– Drop testing

– Salt fog

– Immersion

– Resistance to solvents

– Solderability & soldering heat

– Terminal strength

– Vibration

– Mechanical shock

– Shipping integrity

– Flammability

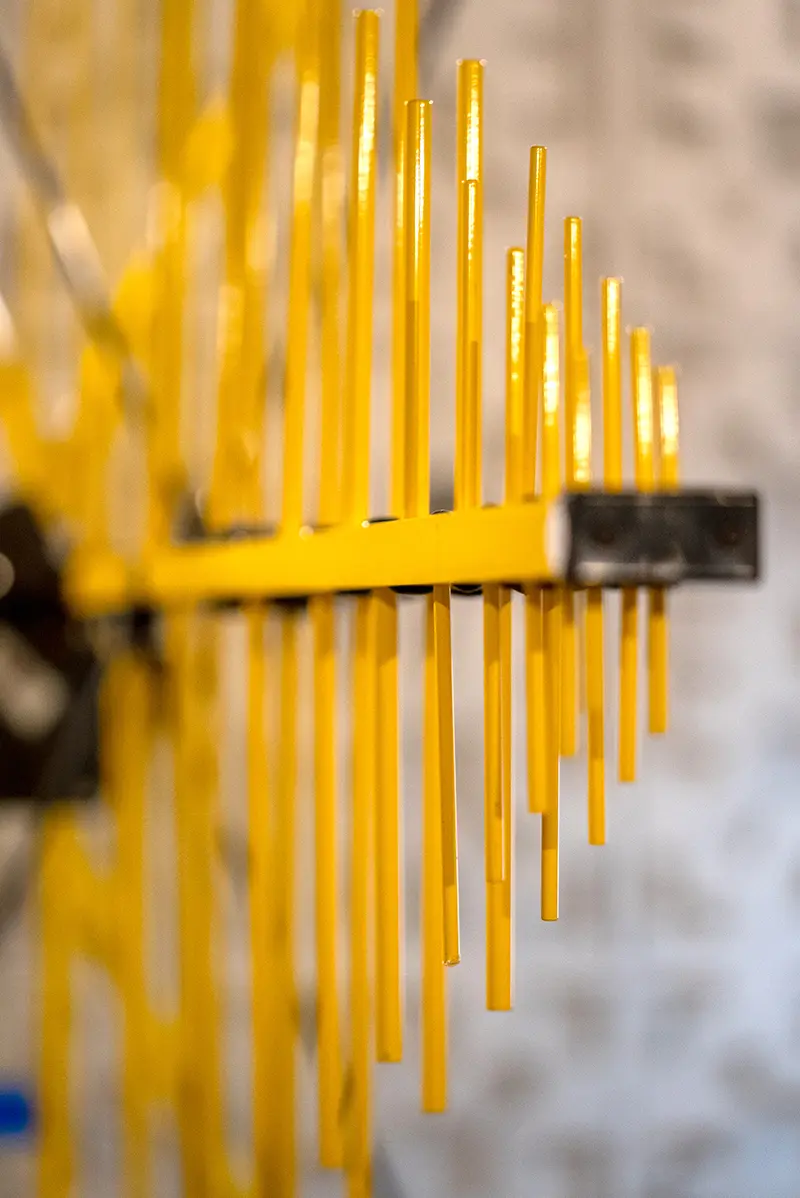

MECHANICAL TEST LABS

Our accelerated life testers for optical and Hall-effect rotary encoders test millions of cycles in a relatively short period of time. Unlike some competitors, the mechanical and electrical life specifications for Grayhill encoders define each cycle as a full rotation of the shaft and the return to its original position. Other mechanical rigs test:

- Vibration

- Front and side-impact

- Abrasion on actuator

ENVIRONMENTAL TEST LABS

Grayhill environmental test chambers can simulate many environmental conditions, including various temperatures, humidity levels and rapid cycling of these conditions. Other environmental tests include:

- Thermal shock

- Liquid seal

- Dust seal

- UV exposure

- Salt spray resitance

- Chemical resistance

ELECTRICAL TEST LABS

With our in-house electrical test labs, Grayhill has the ability to test products against a wide range of electrical conditions, including:

- Electro-Magnetic Compatibility (EMC)

- Electro-Static Discharge (ESD)

- Electro-Magnetic Interference (EMI)

- Electrical Noise

- Power Interruption

STAY UP TO DATE WITH OUR BLOG

Learn more about Grayhill and our extensive range of products and services.